Intrinsic Safety Solutions

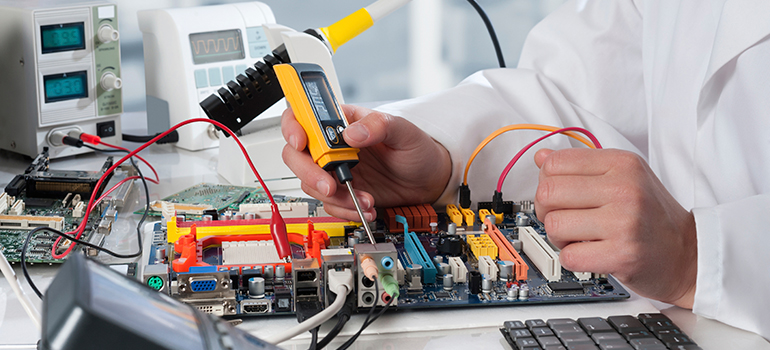

When designing Intrinsically Safe products, Testing and Certification are essential

What is Intrinsic Safety?

Intrinsic safety is a protection method for the safe operation of electrical equipment in hazardous locations that prevents explosions from occurring by ensuring that the energy transferred to a hazardous area is well below the energy required to initiate an explosion, which can take the form or a hot surface or an electrical spark. Intrinsic safety is an electrical design approach and one of the key methods used to protect electrical equipment in hazardous locations.

Intrinsic Safety Benefits

Products that have been designed to be intrinsically safe are usually suitable for use in all Hazardous Location divisions, zones, and environments due to the fact that this protection method requires the most stringent certification standards. The concept of protection behind Intrinsic Safety involves ensuring low energy levels to prevent incendive sparking and hotspots.

Some benefits of using intrinsic safety for products in these environments include:

- Increased safety: Intrinsic safety systems are designed to prevent ignition of flammable or explosive materials by limiting the amount of energy that can be supplied to electrical equipment. This reduces the risk of fire or explosion in hazardous environments.

- Improved reliability: Intrinsic safety systems are designed to be reliable and durable, with self-monitoring features that detect and correct any problems before they become a hazard. This helps ensure the system will continue to function properly even in harsh or hazardous environments.

- Lower costs: Intrinsic safety systems can be less expensive than other safety systems, as they do not require elaborate protective measures, such as explosion-proof enclosures.

- Easy to install: Intrinsic safety systems are typically easier to install than other safety systems, as they do not require complex electrical connections or modifications to existing equipment

- Versatility: Intrinsic safety systems can be used in a wide range of hazardous environments, including petrochemical plants, oil and gas refineries, and chemical processing facilities.

Overall, intrinsic safety provides a high level of safety and reliability in hazardous environments, while also being cost-effective and easy to install.

8 Ways to Expedite the Intrinsically Safe Product Certification Process

Download the White Paper

Intertek's Intrinsic Safety Solutions

Due to the highly complex testing and certification requirements of a product that is intended to be intrinsically safe, Intertek can provide clients with a specialized Preliminary review process to walk you through the standards and requirements associated with this protection method.

We offer two service levels, including:

Limited Overview

- Simple review of temperature and spark ignition

- No formal assessment or calculations performed

Full Assessment

- Full analysis of temperature and spark ignition

- Must provide schematics

- Must provide full Bill of Materials

To learn more about intrinsic safety, hazardous area classifications and how to approach your intrinsic safety project, click the button above to download our white paper.

Knowledge Center

- Hazardous Locations & Explosive Atmospheres Equipment Certification Requirements Webinar Series

- Guide to Equipment Certification Requirements for Hazardous Locations Poster

- IEC 60079-25 for Intrinsically Safe Electrical Systems: Edition 3

- IEC/EN 60079-6 Part 6: Equipment Protection by Liquid Immersion "o"

- Guide to Hazardous Location Equipment Marking

- SATELLITE Data Acceptance Program for Hazardous Locations

- Lighting for Hazardous Locations Fact Sheet

- China CCC Ex: Hazardous Locations Product Compliance White Paper

- FAQs for Product Compliance in Hazardous Locations

- UAE ECASEx: Unit Verification Webinar Recording

- Transition from EN 13463 to EN ISO 80079 Webinar

- Flammable Refrigerants: Comprehensive Assurance Fact Sheet

- IECEx Non-Electrical: Regulatory Guide to Non-Electrical Equipment in Hazardous Locations

Events

- North America: Year-round CompEx Course Schedule

- Intertek Chester UK facility including CompEx course modules and descriptions

Resources

- Client Testimonials

- ETL Mark The Industry's Fastest Certification Program

- Functional Safety Services

- Field Evaluation

- On-site Design Review

- Certification Program for Industrial Control Panels (ICP)

- EMC Testing